Commissioning

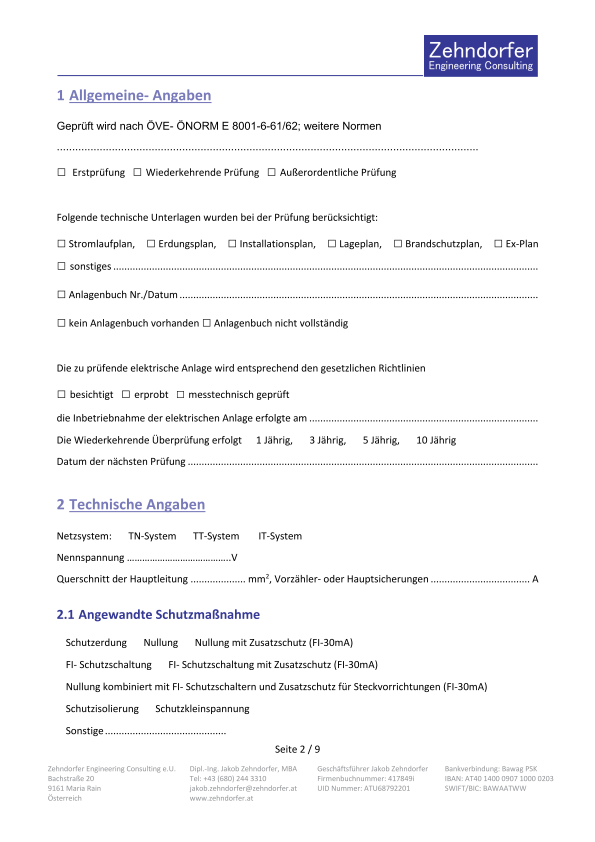

At commissioning the electrical installation is verified according to the respective standards and regulations for construction or extension (e.g. BS 7671 or DIN VDE100)

It consists of the following steps:

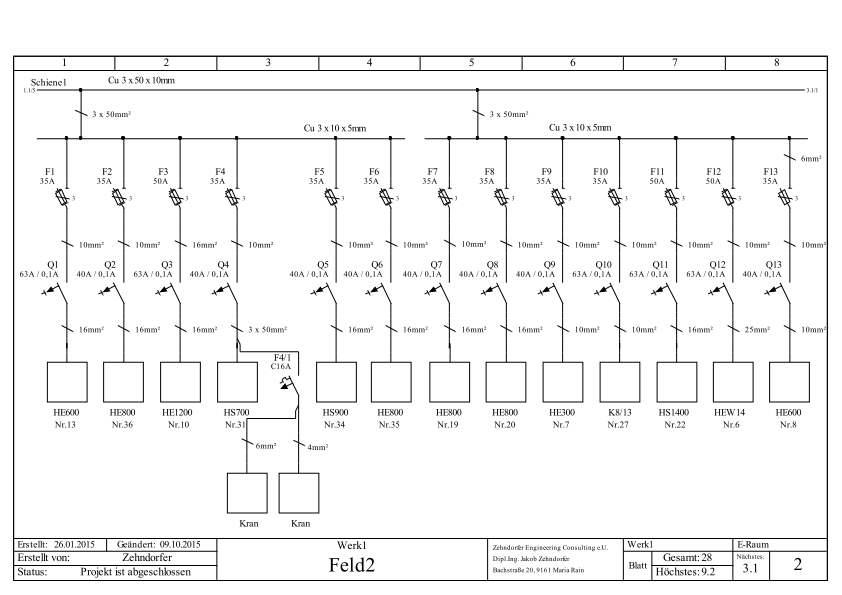

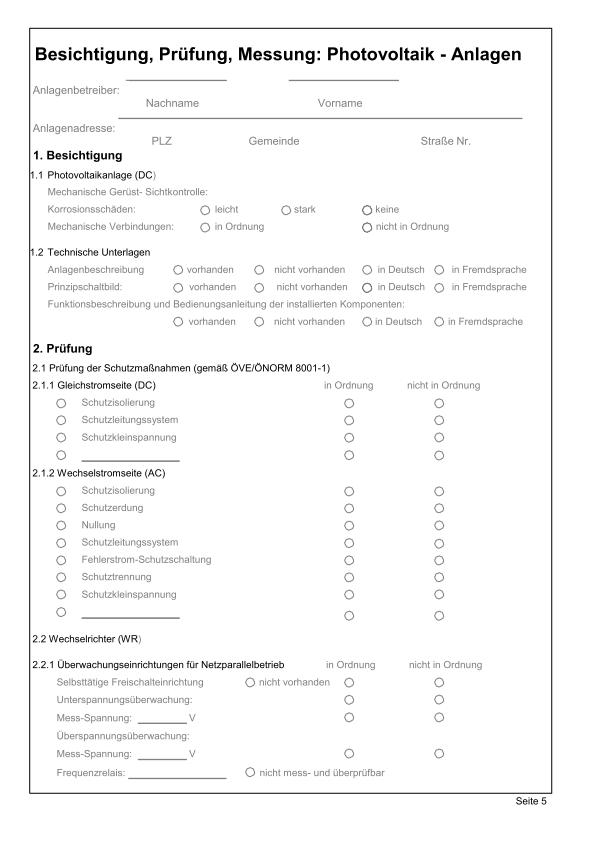

- Visual inspection (e.g. electrical safety gear, cable dimensions, rating of switches, fuses, miniature circuit breakers, molded case circuit breakers)

- trial runs and functional checks

- Measurement of electrical parameters (such as grounding, loop resistance, isolation resistance, residual current protection)

- Verification of plant documentation

The commissioning report ensures, that the plant can be started-up in a save wy and according to the relevant standards and regulations. It is a mandatory part of the plant documentation.

Plant DocumentationFor each electrical plant the regulations (e.g. BS 7671 or VGB R171) require a plant documentation, which has to report the following data and plans

The plant documentation has to be compiled and filed by the construction company. In case no plant documentation is available a replacement plant documentation has to be compiled a the recurring inspection. |

Recurring Electrical Inspection

The purpose of the recurring inspection according to BS 7671 or VDE 100 is the assessment and reporting of all electrical plant data.

Electrical devices and plants are subject to aging, which can cause deterioration of electrical parameters (e.g. isolation, conductance, contact). Old safety gear and switches often do not provide sufficient protection resulting in dangers of electric shocks or danger of fire.

The recurring inspection is typically stipulated in the permits of commercial buildings. It gives the client, the authorities and insurance companies the needed confirmation about the safe and flawless state of teh plant.

The measurements at the recurring electrical inspection are similar to those at plant commissioning. However, special attention is paid to the chronological changes of electrical parameters.

Lightning Damage Assessment

Lightning can destroy electrical appliances directly or indirectly. Appliances connected to the electric sockets in a building that is hit by flash lightning are especially prone to damage, when an overvoltage of the lightning across the earthing resistance, this can lead to dangerous overvoltages in electrical appliances.

A professional Lightning Protection System according to BS EN 62305 with sufficient dimensioning of lightning rods, lightning conductors and surge arrestors helps to reduce the impact of lightning events. However there could still be single overvoltage events, damaging the input of the device (e.g. the mains adapter) or sensitive electronic parts inside a device.

A Lightning Assessment will clarify the kind and of the electrical damage, the damaging process and the verifiable and measureable impact of the damage. Next to optical checks several electrical measurements are done to reconstruct the entrance path of the overvoltage.